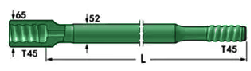

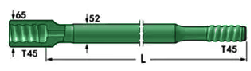

Product name: T45 Thread 4270mm Length Male-Male Connection Extension Rod For

Mineral Exploration Drilling

Product category: Drilling rod

Threaded Connection: T45

Length: 3660mm

KINGDRILLING thread drill

rods are produced from high-intensity alloy steel. All trails and

threads are created using high-precision CNC machines. The thread

is formed by induction hardening, followed by rapid heating and

cooling. Precision temperature-controlled heat treatment equipment

extends the drill

rod's service life and enhances its mechanical qualities.

Holistic carburization raises the carbon content of the drill

rod's outer layer while also hardening the exterior steel body. The

solid thread fits perfectly with the inner wall of the drill bits,

allowing for high precision and efficiency in complex rock and

terrain rough drilling tasks such as roadway tunneling, underground

mineral, and open pit drilling.

KINGDRILLING thread drill rod parameters:

| THREAD | description | Length | Diameter | Weight approx kg |

| mm | Foot | mm | inch |

| T45 | Extension rod T45-Round45-145 | 1830 | 6' | 46 | 1 3/4 | 21.6 |

| Flushing hole 17mm | 2435 | 8' | 46 | 1 3/4 | 28.3 |

| Wrench flat 38mm | 3050 | 10' | 46 | 1 3/4 | 35.2 |

| 3660 | 12' | 46 | 1 3/4 | 42.1 |

| 4270 | 14' | 46 | 1 3/4 | 48.9 |

| 5530 | 18' | 46 | 1 3/4 | 63 |

| 6095 | 20' | 46 | 1 3/4 | 69.3 |

| T45 | MF-rpd T45-Round46-T45 | 1525 | 5' | 46 | 1 3/4 | 21.2 |

| Flushing hole 17mm | 1830 | 6' | 46 | 1 3/4 | 24.6 |

| 3050 | 10' | 46 | 1 3/4 | 38.2 |

| 3660 | 12' | 46 | 1 3/4 | 45 |

| 4270 | 14' | 46 | 1 3/4 | 51.9 |

| 5530 | 18' | 46 | 1 3/4 | 66 |

| 6095 | 20' | 46 | 1 3/4 | 72.3 |

| T45 | Guide speedrod T45-found52-145 | 3050 | 10' | 52 | 2 | 46.6 |

| Flushing hole 21.5mm | 3660 | 12' | 52 | 2 | 55.8 |

| 4270 | 14' | 52 | 2 | 63.8 |

| 5530 | 18' | 52 | 2 | 81.5 |

| 6095 | 20' | 52 | 2 | 89.4 |

| THREAD | Guide Tube | Length | Diameter | Weight approx kg |

| mm | inch | mm | inch |

| T45 | Guide tube | 1220 | 4' | 64 | 2 1/8 | 12.6 |

| D64 for bits from 76-89mm and D76 for bits frcm 89-102mm | 1525 | 5' | 64 | 2 1/8 | 14 |

| 1830 | 6' | 64 | 2 1/8 | 17.4 |

| 3050 | 10' | 64 | 2 1/8 | 28.3 |

| 3660 | 12' | 64 | 2 1/8 | 32.8 |

| 1830 | 6' | 76 | 3 | 40 |

| 3660 | 12' | 76 | 3 | 77.8 |

Order Guide: Thread type + Diameter + length

KINGDRILLING thread drill rod advantages:

- Stable and Reliable Speed: Male-Male Connection Extension Rods guarantee stable and reliable speed during operation, ensuring

precise drilling results every time.

- High-efficiency working: For optimal performance, our Male-Male Connection Extension Rods provide high-efficiency working, allowing you to complete

drilling tasks quickly and efficiently.

- Fast and efficient service: We prioritize customer satisfaction

and provide fast and efficient service to promptly assist and

support all your drilling needs.

- Customizable: Customized to your exact requirements, our Male-Male Connection Extension Rods offer customization options to suit different drilling

applications and personal preferences.

- COMPETITIVE PRICE: Enjoy top-of-the-line drilling equipment at a

competitive price, making our Male-Male Connection Extension Rods an affordable solution for professionals.

FAQ:

1. What is the general structure of a friction-welded drill pipe?

Friction welding connects the drill pipe to the pipe body via the

drill pipe's internal and external thread joints. The drill pipe

rotates under the control of a turntable or power head, which sends

power to the bit at the bottom of the hole and distributes drilling

fluid to its cutting surface. The drill pipe is critical to the

overall drilling construction process.

2. What is the use of a drill rod?

Drill pipe is commonly used for hydrological exploration,

geological drilling, oil and gas exploration, and other

applications.

3. How to maintain and manage drill pipe after use?

After the drilling operation is completed, the drill tools are

neatly placed on the drill pipe rack according to different

specifications, wall thickness, water hole size, steel grade and

grading grade. Clean, rinse and dry the inside and outside surface of drill tool,

joint thread and shoulder sealing surface with clean water in time. Check the drill pipe surface for cracks and nicks, whether the

thread is intact, whether the joint is eccentric, whether the

shoulder surface is flat and scratched, whether the pipe body is

bent or squeezed, whether there is foreign matter inside and

outside. The drill pipe surface exists. Corrosion, pitting and other defects. If conditions exist, ultrasonic inspection should be carried out

regularly on the drill pipe body and magnetic particle inspection

on the thread part to reduce the probability of joint thread

breakage and drill pipe body leakage. For drilling tools without problems, anti-rust oil should be

applied on the thread and shoulder sealing surface, wear protective

wire and take various protective measures.

MORE INFORMATION: